A control panel in electrical power is an enclosure, usually made of a metal box or plastic molding with critical electrical components that regulate and monitor various mechanical processes. They are energy-efficient systems that require regular planned and preventative maintenance and monitoring of conditions as the most efficient methods. Electrical technicians will have access to control panels to perform fault finding and adjustments and electrical safety testing.

Operators interact with the control panel’s controls to control and operate the process and plant. The control panel components can be used to accomplish various tasks, like checking flow or pressure within pipes and sending signals to shut or open the valve. They are standard equipment and are integral to all industries. They are a necessity for every business. Negligence can bring chaos to any business’s operations and even endanger employees’ lives. This means that secure panel operation is necessary for electrical and non-electrical employees.

Different kinds of panels

Control panels are available in various dimensions and shapes. They range from a tiny box placed on the wall to large rows of cabinets located in specific production areas. Certain controls are situated in a control area under the direction of a small group of production coordinators. In contrast, others are situated close to the machinery and under the direction of a specific group of production employees. Another type of control panel, which is popular in the UK, is called one called the Motor Control Centre or MCC, comprising all of the motor start-up and control equipment that drives large machinery and could, in certain situations, contain high voltage sources like 3.3 1 kV and 11 kV.

Components of the control panel in electrical

The components that make up an electric control panel comprising:

- Attachments

- The Incoming Protection is switched, and the Switching

- Power and Energy Monitoring and Control

- Power Distribution Systems

- Circuit and Load Protection

- Thermal Management

- Motion and Drives

- Security systems

- Programmers, timers, and variable frequency drives

- Power Supplies and Transformers

- Power factor correction as well as surge protection and uninterruptable power supply

- Contactors and relays

Electrical hazards are typical in control panels, with fires, electric shocks, and arcing being the primary danger. Control panels are built with different standards based on age and the country of manufacture. Even though the panels appear uniform outside, the content and layout inside may differ. Along with the dangers of electricity, pneumatic and hydraulic energy and even heat retained can pose a severe risk to anyone who will have to go into it. We suggest taking part in the training programs to be aware of and address these risks with caution.

Here is the basic information on the essential electrical control panel parts that you need to know to get you going.

Read More: Boiler VS. Water Heater: All The Interesting Information You Need To Know

Attachments

An enclosure can be described as the structure for an electronic control panel. It is used to store the components inside it and serves as a barrier between dangers contained within and the people who are outside. The enclosure should be strong enough to protect the environment in which it is typically capable of enduring impact and vibration, heat, dust, liquids, and corrosive chemicals.

The size of the enclosure is also crucial. The smaller ones usually have more devices and pose a higher chance of overheating. However, businesses do not want to waste any space by using the size of a giant metal box too. When dealing with electrical controls panels, you should first be aware of the purpose of their use. This will help you identify if there is poor wiring or inefficient space.

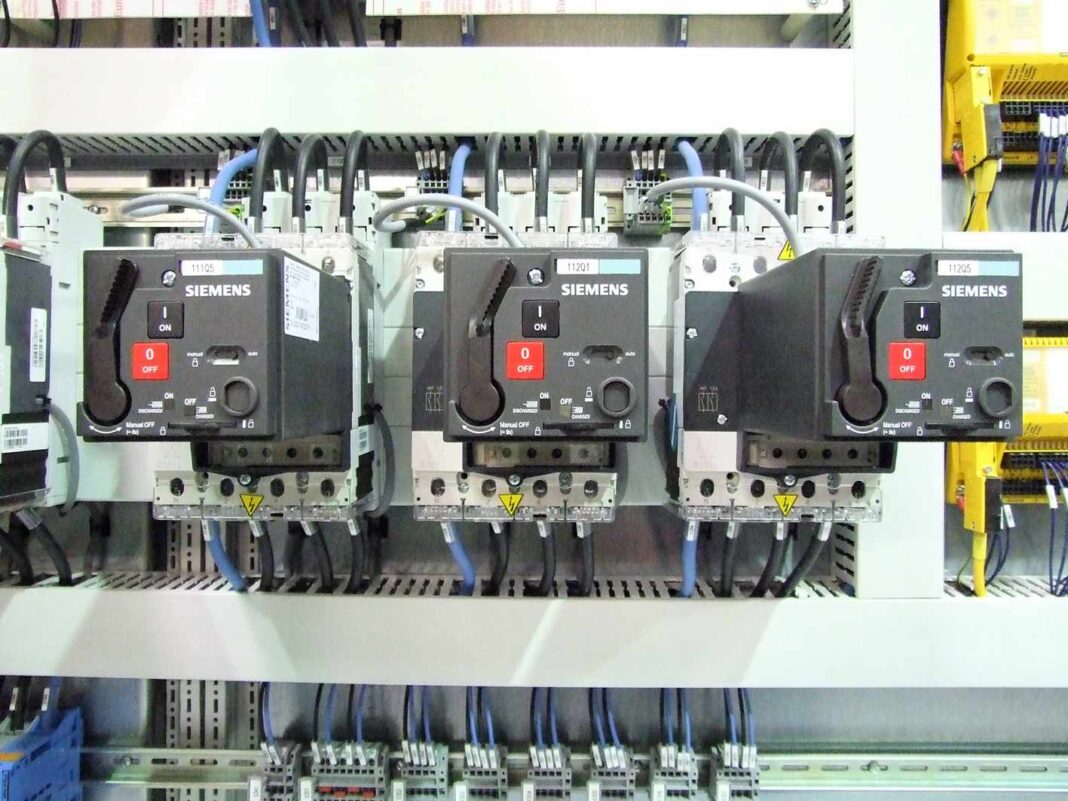

Circuit breaker

In most cases, the power supply to the control panel is accessed via a circuit breaker. Still, this could be simply a disconnecting device with zero fault security in other cases. The particular configurations of your website will differ; however, in most cases, when this device is situated inside the control panel, it is imperative to keep in mind that the connections coming into the device will remain active even when the switch is in an open (off) setting. Also, keep in mind that some parts, such as the power sockets and lighting fixtures, can remain active even when the circuit breaker is turned off.

Power Distribution Systems

Motors and other components are supplied with the mains voltage, usually 400-volt, three-phase, 50 frequency. For motor circuits with three phases, it is doubtful that the neutral power of the power supply will be divided. The output from a distribution transformer travels along the distributor conductor.

The power supply for the end consumers is connected to a distributor conductor. The current flowing through a distributor changes as taps are made at different locations throughout its length. Therefore, while building a distributor conductor, voltage loss along the size is the primary factor to consider.

Control circuits, field wiring which connects to limit switches, and other sensing devices will likely be operating at a lower voltage, which is typically 24-volts a.c. as well as d.c. Even though 110-volt a.c. Systems are widely utilized. It is essential to be cautious with control circuits because potential dangers of electric shock may exist. When an electric shock is not an issue, burning or explosions that result from short-circuiting control circuit wiring could cause property and life safety at risk. Panels could be linked to each other, and an accident in one panel could result in other panels and the equipment connected to it functioning in a non-intentional way.

Control panels are safe for entry.

Many companies have policies to restrict access to control panels for electrical equipment and distribution boards to a select group of people only. Specific policies are absolute, and anyone in violation is severely punished. In other cases, the policy is in place all the time. However, policies are usually neglected when supervisory protection is less, and there is high production demand.

Why do we use electrical control panels?

Electrical control panels are essential components of most industrial and commercial buildings. They are used to control and distribute electrical power throughout the facility. The primary function of an electrical control panel is to regulate the flow of electricity to different equipment and devices, ensuring that they receive the right amount of power at the right time. They also protect the equipment from electrical faults such as overloading, short circuits, and power surges.

The use of electrical control panels provides a safe and efficient way of managing electrical systems. They allow for centralized control and monitoring, which is crucial in large buildings with multiple electrical systems. Control panels also provide the ability to shut down electrical systems in an emergency or when maintenance is required, which helps to reduce the risk of injury and damage to equipment.

Another reason why we use electrical control panels is their ability to increase energy efficiency. Control panels can optimize the operation of electrical systems, reducing energy waste and lowering utility bills. They can also provide real-time data on energy consumption, allowing for more accurate energy monitoring and management.

Final Thoughts

This is essential information about control panels in electrical. After reading this article, you got a basic understanding of the electrical control panel. Electrical control panels are an essential part of electrical systems. There is an extensive range of control panels in electrical. Choose wisely which kind of electrical control panel fulfill your requirements.